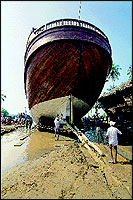

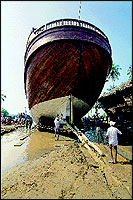

IF you are visiting Calicut, and if you have the time, I suggest you make a quick trip to the ship-building yard at Beypore. It is 11-km south of the city and quite a tourist spot. Regular excursions are taken here, and especially when an Arab dhow is being built for some oil-rich sheikh in the Gulf, or a business tycoon from Bombay. The morning I went, an entire school had been brought to witness the industry, and the toiling ship-builders did not seem to mind the several scarved and capped heads of the girls and boys crowding around them curiously. I made the bone-jarring journey there in 25 minutes, the car winding its way through sleepy coastal villages, to finally come to the estuarine port located at the mouth of the Beypore River.

The yard is at the end of a long road leading to the river, and on the road are small hardware shops selling all kinds of ship-building material from jackfruit wood to one-feet long stainless steel nails, and from fishing nets and lifebuoys to anchors. In between them, somewhat incongrously, stands the Maliyekkal Gift House with its bearded Moplah proprietor K. M. Mubarak enterprisingly selling models of sailing boats and toy ships-in-bottles. The bottles are Johnnie Walker Black. The ships are crafted and painstakingly assembled inside the bottle through its narrow mouth. It is a delicate task requiring great patience, skill and eye for detail.

The yard is at the end of a long road leading to the river, and on the road are small hardware shops selling all kinds of ship-building material from jackfruit wood to one-feet long stainless steel nails, and from fishing nets and lifebuoys to anchors. In between them, somewhat incongrously, stands the Maliyekkal Gift House with its bearded Moplah proprietor K. M. Mubarak enterprisingly selling models of sailing boats and toy ships-in-bottles. The bottles are Johnnie Walker Black. The ships are crafted and painstakingly assembled inside the bottle through its narrow mouth. It is a delicate task requiring great patience, skill and eye for detail.

The same devotion to ship-building, to my utter fascination, was evident inside a fenced-in yard. I stepped through a creaky gate and almost into the large, ribbed innards of a massive dhow under construction. A small army of 35 ship-builders, all skilled carpenters hired at Rs. 190 a day, were hard at work. They were perched here, there and everywhere, hammering, sawing, drilling holes, measuring and marking, while the designer of the dhow, Gokuldas E.P., sat and watched with the bored expression of a ship-builder who has made many dhows. He comes from a family of boat designers that has been in Beypore for 500 years.

The same devotion to ship-building, to my utter fascination, was evident inside a fenced-in yard. I stepped through a creaky gate and almost into the large, ribbed innards of a massive dhow under construction. A small army of 35 ship-builders, all skilled carpenters hired at Rs. 190 a day, were hard at work. They were perched here, there and everywhere, hammering, sawing, drilling holes, measuring and marking, while the designer of the dhow, Gokuldas E.P., sat and watched with the bored expression of a ship-builder who has made many dhows. He comes from a family of boat designers that has been in Beypore for 500 years.

�It is called the Edathumpadikkal family,� he said. �Beypore had four or five families like ours, now only we remain, the others went to build luxury yachts and passenger liners in the Gulf.�

Beypore's ship-building industry is over 1,800 years old. By ship, Keralites mean the uru, or Arab dhow. Local Calicut history has it that the very first uru was commissioned by Cheraman Perumal, the last ruler of Kerala belonging to the Chera dynasty. He embraced Islam and travelled to Mecca to perform the Haj in the uru specially designed for him. Beypore was the naval base of Cheraman Perumal and Kunhali Marakkan, the first naval commander of India who was eventually executed in Goa by the Portuguese. Centuries down the line, Beypore's urus became the dreamboats of the seas, carrying goods and passengers from continent to continent, and bringing fame and fortune to Beypore. That great sea-farer Vasco da Gama found the urus could compete with large mechanised vessels in their capacity to carry cargo across oceans.

�It is called the Edathumpadikkal family,� he said. �Beypore had four or five families like ours, now only we remain, the others went to build luxury yachts and passenger liners in the Gulf.�

Beypore's ship-building industry is over 1,800 years old. By ship, Keralites mean the uru, or Arab dhow. Local Calicut history has it that the very first uru was commissioned by Cheraman Perumal, the last ruler of Kerala belonging to the Chera dynasty. He embraced Islam and travelled to Mecca to perform the Haj in the uru specially designed for him. Beypore was the naval base of Cheraman Perumal and Kunhali Marakkan, the first naval commander of India who was eventually executed in Goa by the Portuguese. Centuries down the line, Beypore's urus became the dreamboats of the seas, carrying goods and passengers from continent to continent, and bringing fame and fortune to Beypore. That great sea-farer Vasco da Gama found the urus could compete with large mechanised vessels in their capacity to carry cargo across oceans.

I found Gokuldas's dhow being built in a huge shed covered with palm leaves that had been constructed along the banks of the river. �Earlier, we used teak wood of the highest quality from the upper ranges of the Nilambur forest to build these dhows. Now those trees are exhausted, so we use the wood of the jackfruit tree, it is sturdy and thick and freely available. One cubic feet of wood costs Rs. 500. The wood is cut and kept out in the sun for a month,� said Gokuldas. It turned out the uru he was making, was the biggest from among 15 he had made in the 15 years he was in business. The cost of the boat was Rs. 1 crore. It had been ordered by somebody from the Gulf. Gokuldas was not giving the customer's name out. What he gave me, instead, were specifications of the dhow: �It is 150 feet long, 40 feet wide, and 25 feet high at its lowest point. It's weight? About 1,200 tonnes! I started building this one a year ago and it will be ready in eight months.�

I found Gokuldas's dhow being built in a huge shed covered with palm leaves that had been constructed along the banks of the river. �Earlier, we used teak wood of the highest quality from the upper ranges of the Nilambur forest to build these dhows. Now those trees are exhausted, so we use the wood of the jackfruit tree, it is sturdy and thick and freely available. One cubic feet of wood costs Rs. 500. The wood is cut and kept out in the sun for a month,� said Gokuldas. It turned out the uru he was making, was the biggest from among 15 he had made in the 15 years he was in business. The cost of the boat was Rs. 1 crore. It had been ordered by somebody from the Gulf. Gokuldas was not giving the customer's name out. What he gave me, instead, were specifications of the dhow: �It is 150 feet long, 40 feet wide, and 25 feet high at its lowest point. It's weight? About 1,200 tonnes! I started building this one a year ago and it will be ready in eight months.�

I kicked around the ship-building yard and made a great discovery. Based on the principles of traditional boat-building in Beypore, no metal but for the foot-long stainless steel nails (costing Rs. 15 each!) is used in the construction of the dhows. Nor are any mechanised or electrical devises used. Like electric saws and drills that, I thought, would have hastened the work and made it much easier. Instead, the carpenters laboured with gigantic hand-held drills and large, long saws whose teeth had to be regularly sharpened. The entire dhow is hand-crafted. The stainless steel nails are a modern touch. Earlier, a dhow's joints were held together by strong jute ropes. More incredible was the discovery that Gokuldas employed no modern drawing methods or calculations to make his dhows. There was nothing on paper, no blueprint. �It is in my mind,� he said to my amazement. �My father passed on the trade to me orally. I tell my carpenters what to do, they work by intuition and experience.�

I kicked around the ship-building yard and made a great discovery. Based on the principles of traditional boat-building in Beypore, no metal but for the foot-long stainless steel nails (costing Rs. 15 each!) is used in the construction of the dhows. Nor are any mechanised or electrical devises used. Like electric saws and drills that, I thought, would have hastened the work and made it much easier. Instead, the carpenters laboured with gigantic hand-held drills and large, long saws whose teeth had to be regularly sharpened. The entire dhow is hand-crafted. The stainless steel nails are a modern touch. Earlier, a dhow's joints were held together by strong jute ropes. More incredible was the discovery that Gokuldas employed no modern drawing methods or calculations to make his dhows. There was nothing on paper, no blueprint. �It is in my mind,� he said to my amazement. �My father passed on the trade to me orally. I tell my carpenters what to do, they work by intuition and experience.�

The dhows are in great demand among traders of the Gulf countries. It was in these boats that goods such as textiles, ivory, spices and scents travelled from the Malabar coast to different parts of the world. They last 50 years easily without any major need for repair or servicing. When Gokuldas has finished this dhow, he will install a 1,500 HP engine onto it, though it is also fitted with a mast and sails. The interiors of the dhow are done by another agency according to the customer's specifications. It is then launched into the sea through a small inlet at Beypore itself. This is quite a ceremony and an astonishing feat executed by experts known as khalasis. The job is done physically, using steel ropes, wooden rollers and rounded logs, wooden pulleys and winches. I asked Gokuldas what was the smallest and cheapest dhow he had made. �It was 45 feet and cost Rs. 30 lakh,� he replied. Did his family own a dhow, I asked. �No,� he said, �Our job is to make and sell dhows, not keep them!�

The dhows are in great demand among traders of the Gulf countries. It was in these boats that goods such as textiles, ivory, spices and scents travelled from the Malabar coast to different parts of the world. They last 50 years easily without any major need for repair or servicing. When Gokuldas has finished this dhow, he will install a 1,500 HP engine onto it, though it is also fitted with a mast and sails. The interiors of the dhow are done by another agency according to the customer's specifications. It is then launched into the sea through a small inlet at Beypore itself. This is quite a ceremony and an astonishing feat executed by experts known as khalasis. The job is done physically, using steel ropes, wooden rollers and rounded logs, wooden pulleys and winches. I asked Gokuldas what was the smallest and cheapest dhow he had made. �It was 45 feet and cost Rs. 30 lakh,� he replied. Did his family own a dhow, I asked. �No,� he said, �Our job is to make and sell dhows, not keep them!�

Gokuldas E. P.

Edathumpadikkal House

P.O. Beypore, Calicut 673015, Kerala.

Mobile: 3509434.

Beypore�s Dhows... Dreamboats Of The Seas!

Beypore�s Dhows... Dreamboats Of The Seas!

The yard is at the end of a long road leading to the river, and on the road are small hardware shops selling all kinds of ship-building material from jackfruit wood to one-feet long stainless steel nails, and from fishing nets and lifebuoys to anchors. In between them, somewhat incongrously, stands the Maliyekkal Gift House with its bearded Moplah proprietor K. M. Mubarak enterprisingly selling models of sailing boats and toy ships-in-bottles. The bottles are Johnnie Walker Black. The ships are crafted and painstakingly assembled inside the bottle through its narrow mouth. It is a delicate task requiring great patience, skill and eye for detail.

The yard is at the end of a long road leading to the river, and on the road are small hardware shops selling all kinds of ship-building material from jackfruit wood to one-feet long stainless steel nails, and from fishing nets and lifebuoys to anchors. In between them, somewhat incongrously, stands the Maliyekkal Gift House with its bearded Moplah proprietor K. M. Mubarak enterprisingly selling models of sailing boats and toy ships-in-bottles. The bottles are Johnnie Walker Black. The ships are crafted and painstakingly assembled inside the bottle through its narrow mouth. It is a delicate task requiring great patience, skill and eye for detail. The same devotion to ship-building, to my utter fascination, was evident inside a fenced-in yard. I stepped through a creaky gate and almost into the large, ribbed innards of a massive dhow under construction. A small army of 35 ship-builders, all skilled carpenters hired at Rs. 190 a day, were hard at work. They were perched here, there and everywhere, hammering, sawing, drilling holes, measuring and marking, while the designer of the dhow, Gokuldas E.P., sat and watched with the bored expression of a ship-builder who has made many dhows. He comes from a family of boat designers that has been in Beypore for 500 years.

The same devotion to ship-building, to my utter fascination, was evident inside a fenced-in yard. I stepped through a creaky gate and almost into the large, ribbed innards of a massive dhow under construction. A small army of 35 ship-builders, all skilled carpenters hired at Rs. 190 a day, were hard at work. They were perched here, there and everywhere, hammering, sawing, drilling holes, measuring and marking, while the designer of the dhow, Gokuldas E.P., sat and watched with the bored expression of a ship-builder who has made many dhows. He comes from a family of boat designers that has been in Beypore for 500 years.  �It is called the Edathumpadikkal family,� he said. �Beypore had four or five families like ours, now only we remain, the others went to build luxury yachts and passenger liners in the Gulf.�

Beypore's ship-building industry is over 1,800 years old. By ship, Keralites mean the uru, or Arab dhow. Local Calicut history has it that the very first uru was commissioned by Cheraman Perumal, the last ruler of Kerala belonging to the Chera dynasty. He embraced Islam and travelled to Mecca to perform the Haj in the uru specially designed for him. Beypore was the naval base of Cheraman Perumal and Kunhali Marakkan, the first naval commander of India who was eventually executed in Goa by the Portuguese. Centuries down the line, Beypore's urus became the dreamboats of the seas, carrying goods and passengers from continent to continent, and bringing fame and fortune to Beypore. That great sea-farer Vasco da Gama found the urus could compete with large mechanised vessels in their capacity to carry cargo across oceans.

�It is called the Edathumpadikkal family,� he said. �Beypore had four or five families like ours, now only we remain, the others went to build luxury yachts and passenger liners in the Gulf.�

Beypore's ship-building industry is over 1,800 years old. By ship, Keralites mean the uru, or Arab dhow. Local Calicut history has it that the very first uru was commissioned by Cheraman Perumal, the last ruler of Kerala belonging to the Chera dynasty. He embraced Islam and travelled to Mecca to perform the Haj in the uru specially designed for him. Beypore was the naval base of Cheraman Perumal and Kunhali Marakkan, the first naval commander of India who was eventually executed in Goa by the Portuguese. Centuries down the line, Beypore's urus became the dreamboats of the seas, carrying goods and passengers from continent to continent, and bringing fame and fortune to Beypore. That great sea-farer Vasco da Gama found the urus could compete with large mechanised vessels in their capacity to carry cargo across oceans. I found Gokuldas's dhow being built in a huge shed covered with palm leaves that had been constructed along the banks of the river. �Earlier, we used teak wood of the highest quality from the upper ranges of the Nilambur forest to build these dhows. Now those trees are exhausted, so we use the wood of the jackfruit tree, it is sturdy and thick and freely available. One cubic feet of wood costs Rs. 500. The wood is cut and kept out in the sun for a month,� said Gokuldas. It turned out the uru he was making, was the biggest from among 15 he had made in the 15 years he was in business. The cost of the boat was Rs. 1 crore. It had been ordered by somebody from the Gulf. Gokuldas was not giving the customer's name out. What he gave me, instead, were specifications of the dhow: �It is 150 feet long, 40 feet wide, and 25 feet high at its lowest point. It's weight? About 1,200 tonnes! I started building this one a year ago and it will be ready in eight months.�

I found Gokuldas's dhow being built in a huge shed covered with palm leaves that had been constructed along the banks of the river. �Earlier, we used teak wood of the highest quality from the upper ranges of the Nilambur forest to build these dhows. Now those trees are exhausted, so we use the wood of the jackfruit tree, it is sturdy and thick and freely available. One cubic feet of wood costs Rs. 500. The wood is cut and kept out in the sun for a month,� said Gokuldas. It turned out the uru he was making, was the biggest from among 15 he had made in the 15 years he was in business. The cost of the boat was Rs. 1 crore. It had been ordered by somebody from the Gulf. Gokuldas was not giving the customer's name out. What he gave me, instead, were specifications of the dhow: �It is 150 feet long, 40 feet wide, and 25 feet high at its lowest point. It's weight? About 1,200 tonnes! I started building this one a year ago and it will be ready in eight months.� I kicked around the ship-building yard and made a great discovery. Based on the principles of traditional boat-building in Beypore, no metal but for the foot-long stainless steel nails (costing Rs. 15 each!) is used in the construction of the dhows. Nor are any mechanised or electrical devises used. Like electric saws and drills that, I thought, would have hastened the work and made it much easier. Instead, the carpenters laboured with gigantic hand-held drills and large, long saws whose teeth had to be regularly sharpened. The entire dhow is hand-crafted. The stainless steel nails are a modern touch. Earlier, a dhow's joints were held together by strong jute ropes. More incredible was the discovery that Gokuldas employed no modern drawing methods or calculations to make his dhows. There was nothing on paper, no blueprint. �It is in my mind,� he said to my amazement. �My father passed on the trade to me orally. I tell my carpenters what to do, they work by intuition and experience.�

I kicked around the ship-building yard and made a great discovery. Based on the principles of traditional boat-building in Beypore, no metal but for the foot-long stainless steel nails (costing Rs. 15 each!) is used in the construction of the dhows. Nor are any mechanised or electrical devises used. Like electric saws and drills that, I thought, would have hastened the work and made it much easier. Instead, the carpenters laboured with gigantic hand-held drills and large, long saws whose teeth had to be regularly sharpened. The entire dhow is hand-crafted. The stainless steel nails are a modern touch. Earlier, a dhow's joints were held together by strong jute ropes. More incredible was the discovery that Gokuldas employed no modern drawing methods or calculations to make his dhows. There was nothing on paper, no blueprint. �It is in my mind,� he said to my amazement. �My father passed on the trade to me orally. I tell my carpenters what to do, they work by intuition and experience.� The dhows are in great demand among traders of the Gulf countries. It was in these boats that goods such as textiles, ivory, spices and scents travelled from the Malabar coast to different parts of the world. They last 50 years easily without any major need for repair or servicing. When Gokuldas has finished this dhow, he will install a 1,500 HP engine onto it, though it is also fitted with a mast and sails. The interiors of the dhow are done by another agency according to the customer's specifications. It is then launched into the sea through a small inlet at Beypore itself. This is quite a ceremony and an astonishing feat executed by experts known as khalasis. The job is done physically, using steel ropes, wooden rollers and rounded logs, wooden pulleys and winches. I asked Gokuldas what was the smallest and cheapest dhow he had made. �It was 45 feet and cost Rs. 30 lakh,� he replied. Did his family own a dhow, I asked. �No,� he said, �Our job is to make and sell dhows, not keep them!�

The dhows are in great demand among traders of the Gulf countries. It was in these boats that goods such as textiles, ivory, spices and scents travelled from the Malabar coast to different parts of the world. They last 50 years easily without any major need for repair or servicing. When Gokuldas has finished this dhow, he will install a 1,500 HP engine onto it, though it is also fitted with a mast and sails. The interiors of the dhow are done by another agency according to the customer's specifications. It is then launched into the sea through a small inlet at Beypore itself. This is quite a ceremony and an astonishing feat executed by experts known as khalasis. The job is done physically, using steel ropes, wooden rollers and rounded logs, wooden pulleys and winches. I asked Gokuldas what was the smallest and cheapest dhow he had made. �It was 45 feet and cost Rs. 30 lakh,� he replied. Did his family own a dhow, I asked. �No,� he said, �Our job is to make and sell dhows, not keep them!�